THIS IS AN EXCERPT FROM THE ARTICLE "FUNCTIONAL PRECISION 3D PRINTING"

Digital Calipers

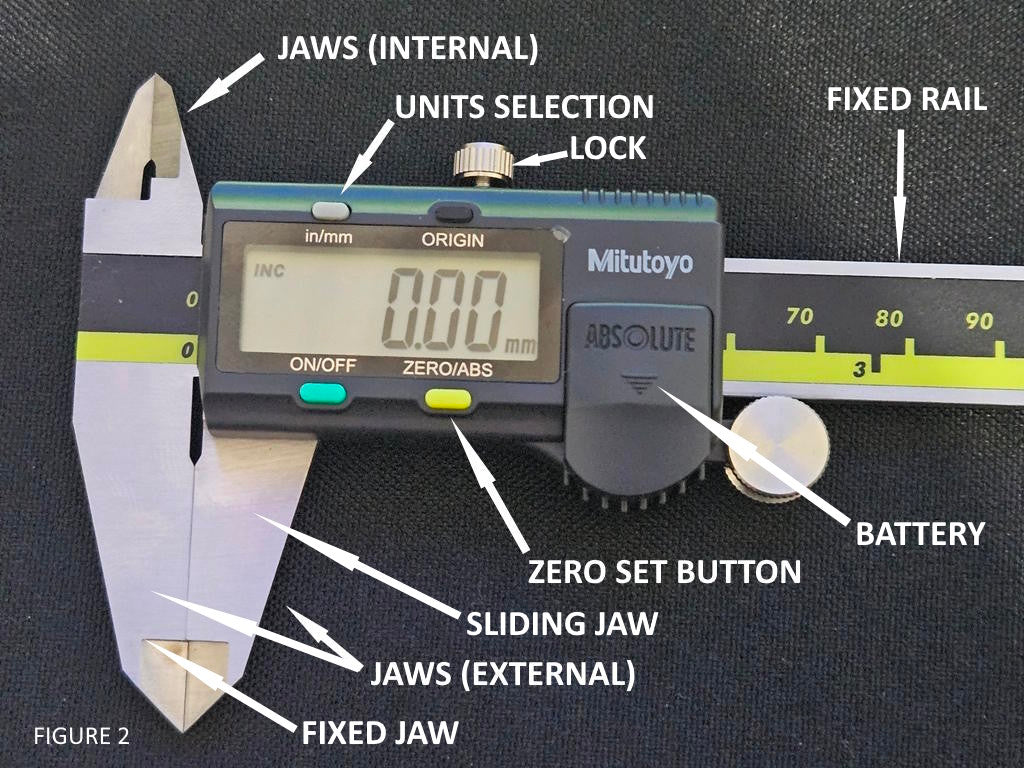

A digital caliper is a must have for precision 3d printing. There are many brands available that run from complete junk at the cheap end to a fine precision tool at the more expensive end. This is one area we recommend not going cheap. A cheap caliper will be inaccurate and inconsistent. Our favorite brands that we have first hand experience with are Mitutoyo and Starrett. There are many cheap brands that are really bad quality, but one that we’ve seen used with some success is Fowler. We strongly advise you not buy one any cheaper than Fowler. Digital calipers should be kept clean. You must select the units you want to measure in, and then set them to zero before use. Clean the faces of the jaws by wiping with your clean finger or a tissue, then close the jaws completely, and press the zero. See figure 2 below.

The primary parts of a digital caliper

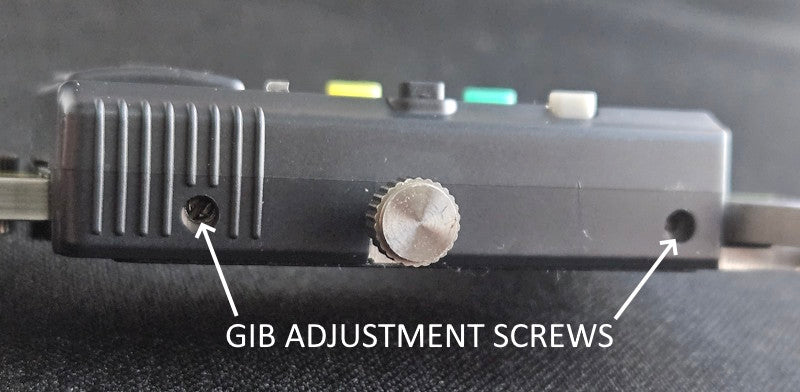

One of the most often unknown or overlooked adjustments on calipers is the gibs. A gib is a wedge device inside the caliper that adjusts the tension of the sliding jaw of the caliper to the fixed rail of the caliper. If the gibs are too loose, the sliding jaw can rock a little (feel slightly loose) on the fixed rail and cause the jaws to not stay parallel. If the gib is too tight, the sliding jaw won't slide anymore. Adjust the screws to the most tension you can for the jaw to still be able to slide smoothly on the fixed rail. You will find this to be a very small amount of tightening tension on the gib adjustment screws.

IMAGE SHOWING THE SCREWS FOR ADJUSTING THE GIBS ON CALIPERS

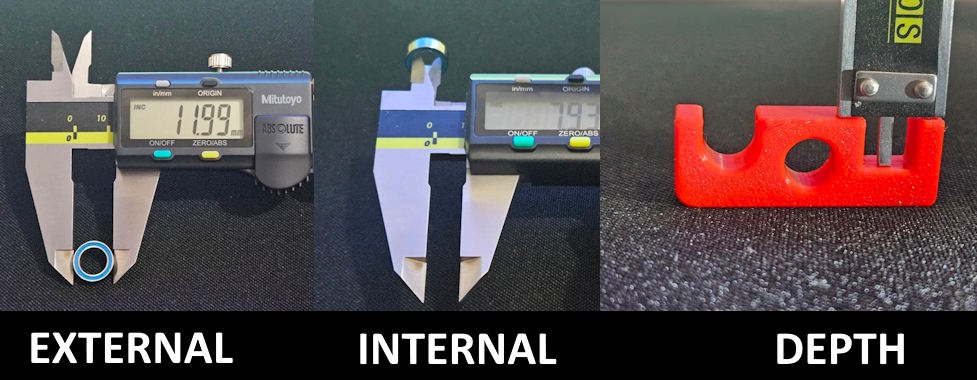

Digital Calipers can be used for measuring outside dimensions, inside dimensions, and also depth by utilizing the rod that protrudes from the center of the rail. Care must be taken not to use too much force in taking measurements. It’s possible to squeeze calipers hard enough to flex the steel and cause measurement errors. Use only enough force to make the jaws fully touch the surfaces to be measured. See figure 3 below.

The three ways that digital calipers can be used to measure

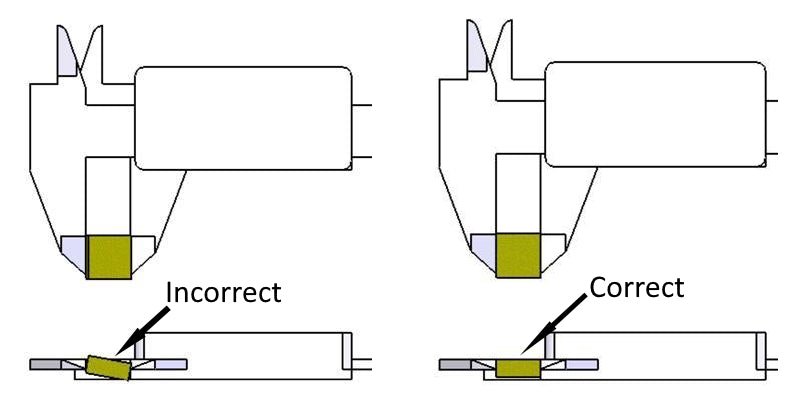

It's important to orient the parts such that the jaws of the calipers are square to the surfaces of the parts. Failure to do so will result in measurement errors.

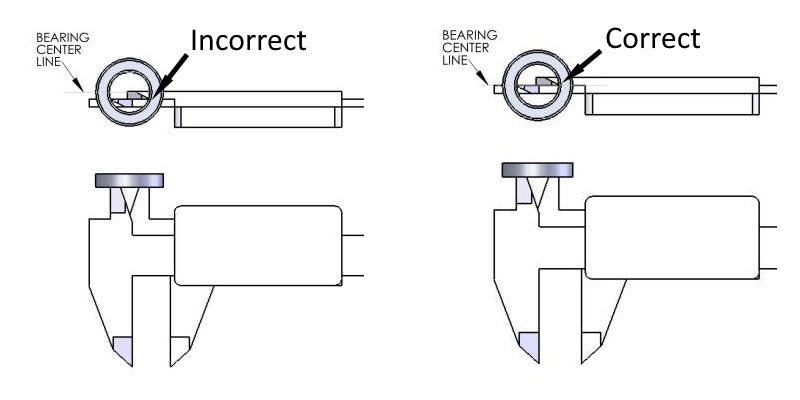

In the example below where the part isn't square with the jaws, the calipers would give a measurement larger than the true value.

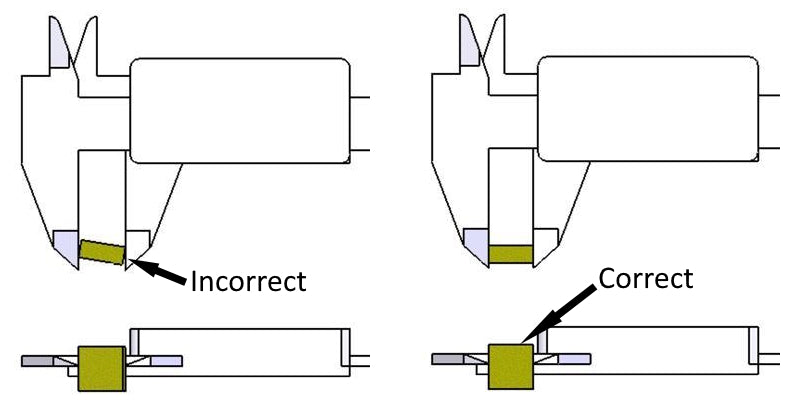

In the example below, failure to get the internal measurement jaws of the calipers on the centerline of the ring will result in a measurement smaller than the true value. Take time to wiggle the parts around and find the centerline by feel. The centerline of an internal curved ring, or a hole, will be where the calipers read the largest value. NOTE: Calipers are not as accurate at measuring a concave curve, or hole, as they are at measuring inside flat surfaces or measuring outside surfaces. This is due to the geometry to the calipers themselves.